Product Description

Stainless Steel Mounted Brackets: The Perfect Solution for Tile Wall Installation

When it comes to tile wall installations, one crucial element that often goes unnoticed is the choice of mounting brackets. These brackets play a significant role in the overall durability and appearance of the tile wall. That's why savvy builders and homeowners alike opt for stainless steel mounted brackets for their tile wall projects. Not only do these brackets provide the necessary support, but they also enhance the visual appeal of the tile wall.

The building factory price of stainless steel mounted brackets makes them an attractive choice for all budgets. Despite being cost-effective, these brackets are designed to withstand the test of time. Stainless steel is known for its exceptional strength and resistance to corrosion, making it an ideal material for mounting brackets. Whether you are installing tiles in a bathroom, kitchen, or any other area prone to moisture, stainless steel mounted brackets will ensure the longevity and structural integrity of your tile wall.

Aside from their durability, stainless steel mounted brackets also offer versatility in terms of design. Available in a range of shapes, sizes, and finishes, these brackets can complement any tile wall style. Whether you prefer a modern and sleek look or a more traditional and ornate design, there will be a stainless steel bracket that matches your aesthetic preferences perfectly. This level of customization allows you to create tile walls that not only serve their purpose but also elevate the overall ambiance of the space.

Another advantage of stainless steel mounted brackets is their ease of installation. With their precise measurements and standardized designs, these brackets can be effortlessly mounted on any wall surface. This not only saves time but also reduces the risk of damage during the installation process. Additionally, the seamless integration of stainless steel mounted brackets into the tile wall adds a professional touch to the overall project.

Our Advantages

|

Wugao

|

Others

|

|||

|

Frame Material

|

Stainless Steel

|

Zinc Plated Steel

|

||

|

Frame Assemble

|

Factory Pre-Assembly

|

Onsite Assembly

|

||

|

Installation

|

More faster,easier and flexiable to connect and fix tightly with Wall and ladding via pattened Pre-assembled Frame to use

accessories,Save cost of operation time and labor |

Onsite assembly with complicated operation

|

||

|

Welding Onsite

|

No Need

|

Yes

|

||

|

Anti-rusty Treatment After Welding

|

No Need

|

Yes

|

||

|

Noise and Pollution Onsite

|

No

|

Yes

|

||

|

Cladding Maintenence

|

More easier

|

Normal

|

||

|

System Overall Life

|

More 50 years withtout frame maintenence

|

About 20 year with cost of parts maintenence

|

||

|

Applied Cladding

|

Stone, granite, marble, tile, terracotta, ceramics, glass, aluminum honeycomb boards etc.

|

Specific

|

||

Detailed Images

Aluminum alloy frames,

Groove type and back bolt type dry hanging for tiles and marble.

Aluminum alloy frame,

Groove type dry hanging for granite.

Aluminum alloy frame,

Our Service

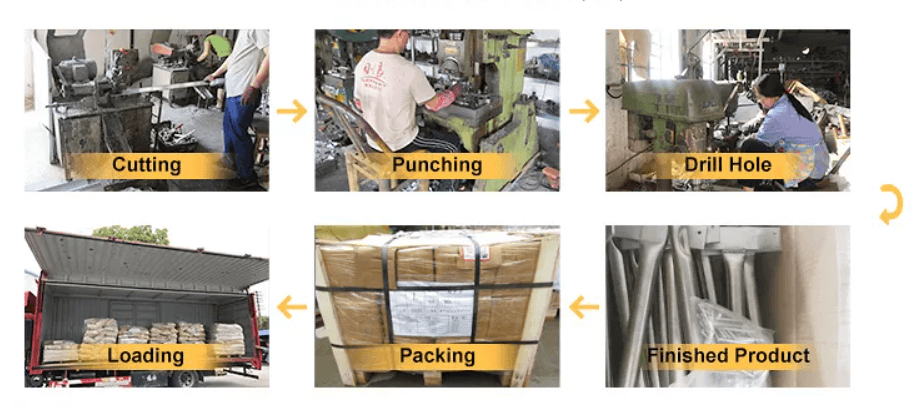

PRODUCTION PROCESS

We can make many styles of building embedded parts,

you provide drawings and requirements, and we can do

the rest

We can use the most advanced mold design software Auto CAD to

design accessories for you

Packing & Delivery

|

Packaging

|

|

|

Size

|

123(L) * 456 (W) * 789 (D)

|

|

Weight

|

1.2 T

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

Packaging

|

|

|

Size

|

123 (L) * 456 (W) * 789 (D)

|

|

Weight

|

1.2 T

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

-

The factory produces aluminum alloy processing ...

-

Stone wall support system Aluminum alloy profil...

-

Factory Wholesale Aluminum Mounting Bracket Pro...

-

Top Quality Fashionable Aluminum Alloy Fixing S...

-

Durable Pin Type Aluminum Cladding Bracket for ...

-

Premium Curtain Wall Hardware Anchors from China