The dry-hung column support point-hung system for aluminum plate curtain walls is a structural system used for the installation of aluminum plate curtain walls. It uses column supports to fix aluminum plates to the main structure of the building through point hanging, creating a beautiful, solid and practical facade for the building. This system is widely used in modern architecture, especially for projects that pursue a simple appearance and efficient construction.

Features of the column support

Strong load-bearing capacity : As the main load-bearing components, the columns are usually made of high-strength aluminum alloy or steel. It has sufficient strength and rigidity to withstand various external forces such as the self-weight of aluminum plates, wind loads, and seismic actions, ensuring the stability and safety of the curtain wall structure.

Flexible installation : The installation position and spacing of the columns can be flexibly adjusted according to the architectural design and the size of the aluminum plates. This enables the system to adapt to building facades of different shapes, sizes and layouts, meeting diverse design requirements.

Good durability : After undergoing special surface treatments such as hot-dip galvanizing and fluorocarbon spraying, the column support has excellent corrosion resistance and can be used for a long time under different environmental conditions, reducing maintenance and replacement costs.

System composition

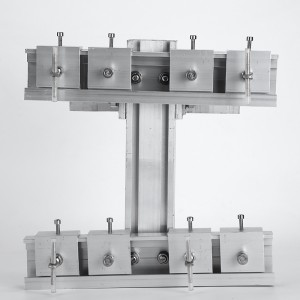

1. Column

It is the core load-bearing component of the system and is generally installed vertically on the main structure of the building. The materials of the columns are usually aluminum alloy and steel. Aluminum alloy columns are light in weight and corrosion-resistant, and are suitable for most buildings. Steel columns have high strength and are suitable for large buildings with high requirements for load-bearing capacity. The cross-sectional shape and size of the columns are designed based on the height, span and force conditions of the curtain wall.

2. Crossbeam

It is horizontally installed between the columns and its main function is to connect the columns and fix the aluminum plates. The crossbeams and columns are reliably connected through connectors to form a stable frame structure. The spacing of the crossbeams is determined based on the size of the aluminum plates and the force requirements to ensure that the aluminum plates can be evenly stressed.

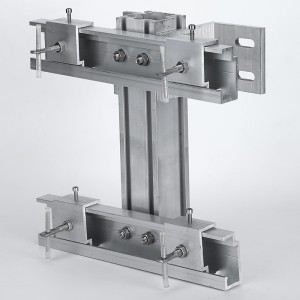

3. Click to hang accessories

Including hanging seats, hanging pieces, etc., they are the key components for realizing the point-hanging installation of aluminum plates. The hanging seat is usually fixed on the crossbeam, and the hanging piece is connected to the embedded part or connecting part on the back of the aluminum plate. The aluminum plate is firmly fixed to the frame structure through the cooperation of the hanging seat and the hanging piece. The design and quality of point-hanging accessories directly affect the installation accuracy and connection reliability of aluminum plates.

4. Sealant strips and sealant

It is used for sealing the joints between aluminum plates to prevent rainwater, air and dust from entering the interior of the curtain wall. Sealing rubber strips have excellent elasticity and weather resistance, and can effectively fill gaps, playing a role in sealing and buffering. Sealant is used for further sealing and waterproofing to ensure the air tightness and water tightness of the curtain wall.

Installation process

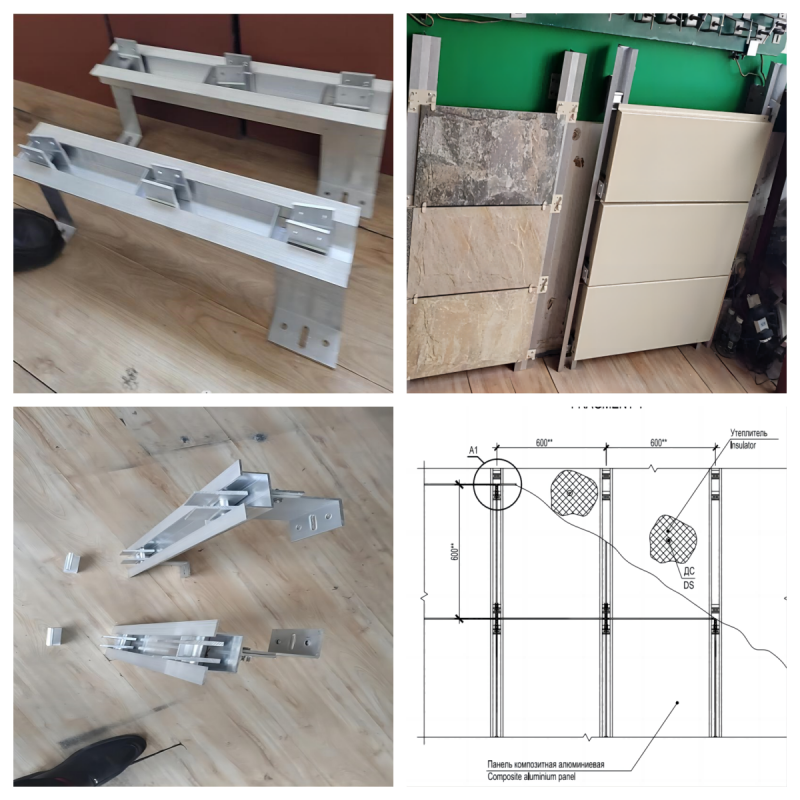

1.Measurement and Layout

According to the design drawings and the actual situation on site, precisely measure and mark the installation position lines of the columns and beams on the main structure of the building. Measurement and layout are the key steps to ensure the installation accuracy of curtain walls, and the error should be controlled within an extremely small range.

2. Column installation

Use connecting pieces to fix the columns to the main structure of the building according to the marking positions. During the installation process, the verticality and levelness of the columns must be strictly controlled. The installation accuracy of the columns can be ensured by adjusting the bolts or washers of the connecting parts. After the installation is completed, inspect and accept the columns to ensure they meet the design requirements.

3. Beam Installation

After the columns are installed properly, install the crossbeams. Firmly connect the crossbeam to the column through the connecting piece, and adjust the levelness and spacing of the crossbeam. The installation quality of the crossbeam directly affects the flatness of the aluminum plate installation and the overall appearance effect.

4. Aluminum Plate installation

Connect and fix the aluminum plate to the crossbeam through point-hanging accessories. When installing, pay attention to the arrangement sequence, direction and width of the joint of the aluminum plates to ensure that the joints between the aluminum plates are tight and flat. At the same time, appropriate protection should be provided for the aluminum plates to prevent surface scratches or damage during installation.

5. Sealing treatment

After the installation of the aluminum plates is completed, the joint seams should be sealed. First install the sealing rubber strip, and then apply the sealant on the outside of the rubber strip. The sealing treatment should be uniform and full to ensure a good sealing effect.

Application advantages

- Elegant and generous : Aluminum plates come in a wide range of colors and surface treatment processes, which can meet the needs of different architectural styles. The point-hanging installation method makes the joints between the aluminum plates more concise and neat, creating a modern and fashionable architectural appearance.

- Construction Efficiency : Compared with the traditional wet-laying installation method, the installation process of the dry-hanging column support point-hanging system is simpler and faster. All components can be prefabricated in the factory and assembled on site, which greatly shortens the construction period and improves the construction efficiency.

- Reliable quality : This system forms a stable frame structure through columns and crossbeams, and point-hung accessories ensure the firm connection of aluminum plates, which can effectively resist various external forces and guarantee the quality and safety of the curtain wall.

- Easy maintenance : If the aluminum plate is damaged or needs to be replaced, simply remove the corresponding point-hanging accessories and the aluminum plate can be easily taken off for repair or replacement.