Applications of Aluminum Alloy Dry Hanging

1. Facades: The dry hanging system revolutionizes the process of building facades. It provides an aesthetically pleasing solution, allowing architects and designers to create unique and visually appealing exteriors.

2. Interior Walls: Aluminum alloy dry hanging systems are also suitable for interior walls. They can be utilized to partition spaces or create unique designs using lightweight materials.

3. Signage and Canopies: Businesses often require signage or canopies to attract customers. The use of aluminum alloy dry hanging systems ensures a secure and durable suspension for signs and canopies, enhancing their effectiveness.

The Aluminum Alloy Dry Hanging system is an innovative and versatile solution that offers numerous benefits for construction projects. Its strength, durability, lightweight nature, and ease of installation make it a superior alternative to traditional hanging systems. By utilizing this method in facades, interior walls, and signage or canopy installations, construction professionals can achieve exceptional results while minimizing costs and maximizing efficiency. Embracing this advanced technology will undoubtedly lead to impressive and sustainable architectural designs, shaping a brighter future for the construction industry.

Product Advantages

Our products can be used in stone, granite, marble, tile, terracotta, ceramics, glass, aluminum honeycomb boards etc, which widely using in Europe now. The fixing method have hundreds of fixing methods, we can support whole fixing system or accessories. which the fixing system/bracket can be used for construction buildings exterior wall facade stone anchoring.

|

Wugao

|

Others

|

|||

|

Frame Material

|

Aluminum Alloy/SS

|

Zinc Plated Steel

|

||

|

Frame Assemble

|

Factory Pre-Assembly

|

Onsite Assembly

|

||

|

Installation

|

More faster,easier and flexiable to connect and fix tightly with Wall and ladding via pattened Pre-assembled Frame to use

|

Onsite assembly with complicated operation

|

||

|

Welding Onsite

|

No Need

|

Yes

|

||

|

Anti-rusty Treatment After Welding

|

No Need

|

Yes

|

||

|

Noise and Pollution Onsite

|

No Need

|

Yes

|

||

|

Cladding Maintenence

|

More easier

|

Normal

|

||

|

System Overall Life

|

More 50 years withtout frame maintenence

|

About 20 year with cost of parts maintenence

|

||

|

Applied Cladding

|

Stone, granite, marble, tile, terracotta, ceramics, glass, aluminum honeycomb boards etc.

|

|||

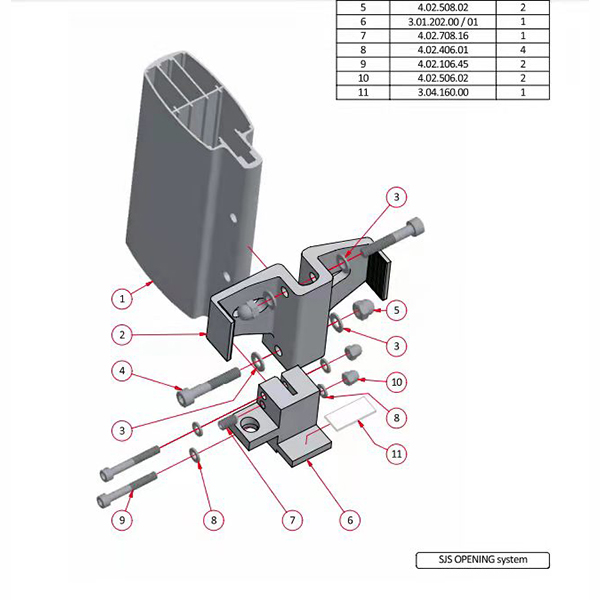

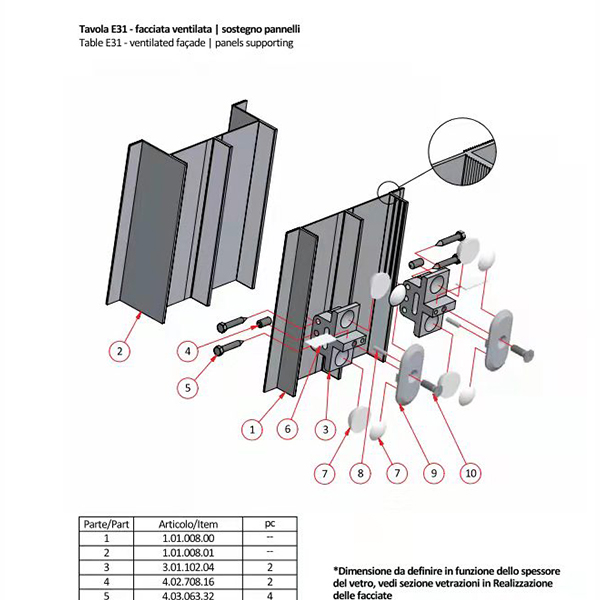

Detailed Images

Aluminum alloy frames,

Groove type and back bolt type dry hanging for tiles and marble.

Aluminum alloy frame,

Groove type dry hanging for granite.

Aluminum alloy frame,

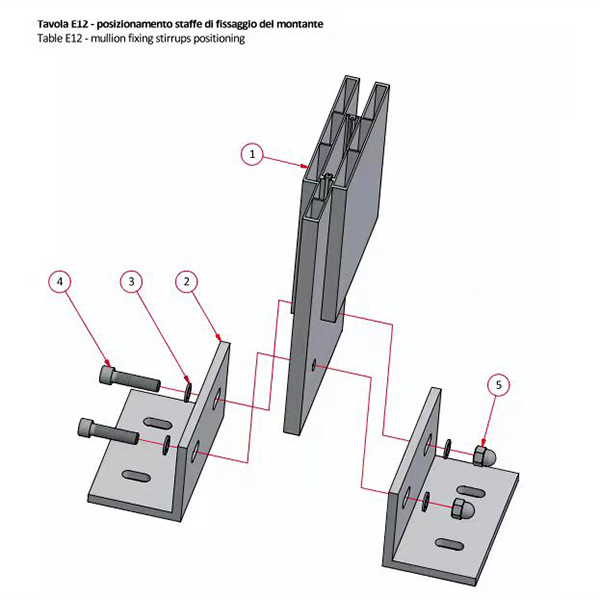

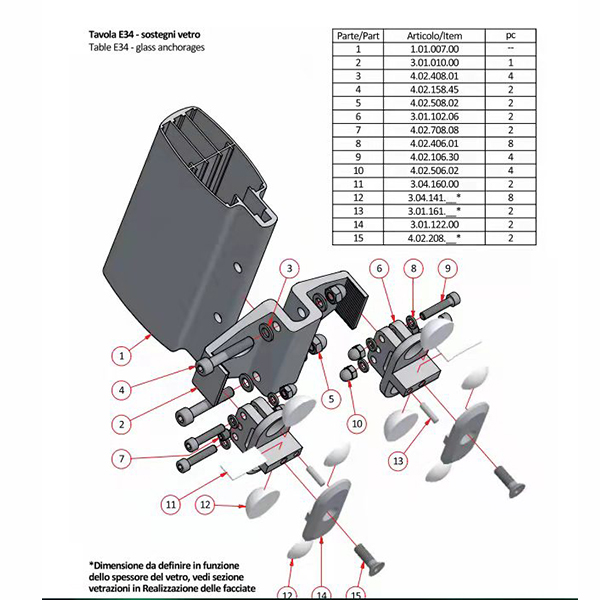

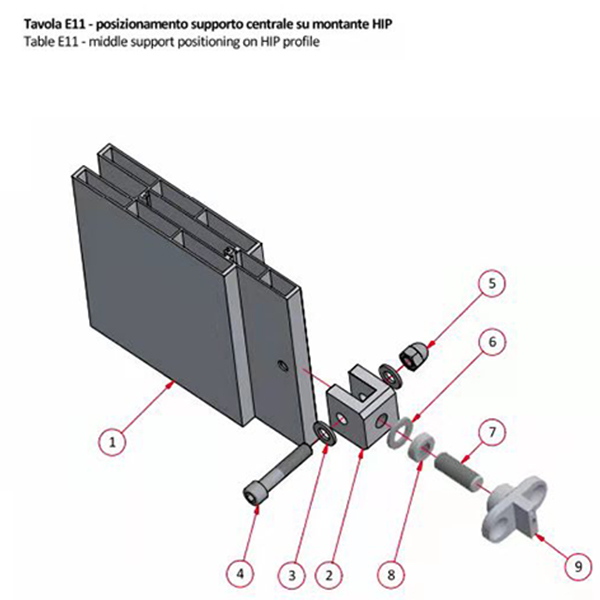

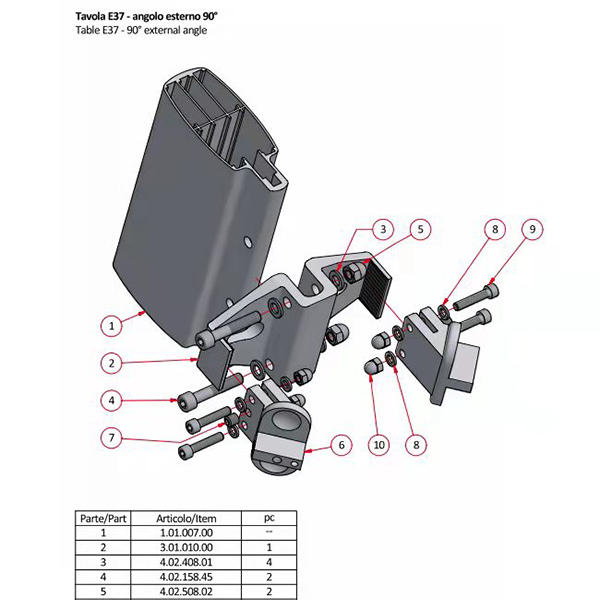

Operating Instructions

Our Service

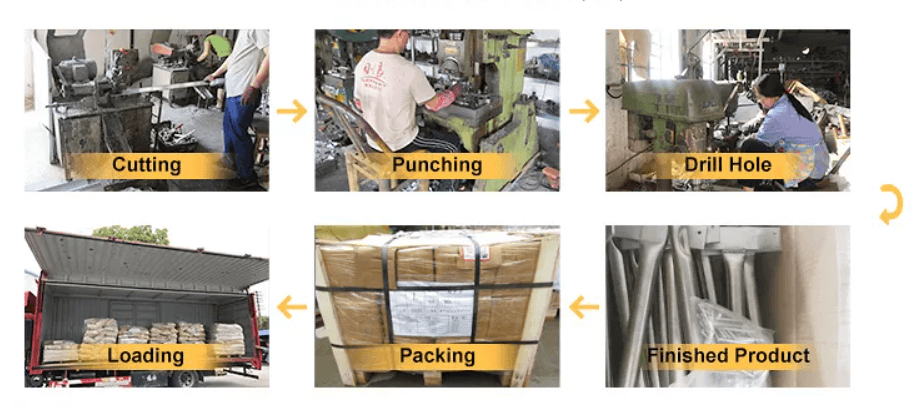

PRODUCTION PROCESS

We can make many styles of building embedded parts,

you provide drawings and requirements, and we can do

the rest

We can use the most advanced mold design software Auto CAD to

design accessories for you

Packing & Delivery

|

Packaging

|

|

|

Size

|

123(L) * 456 (W) * 789 (D)

|

|

Weight

|

1.2 T

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

Packaging

|

|

|

Size

|

123 (L) * 456 (W) * 789 (D)

|

|

Weight

|

1.2 T

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|